la scène : infrastructure & éclairage

Que ce soit dans une tente, dans un amphithéâtre, dans un arena, dans une petite salle ou en festival, Radiohead prend soin de la scène. Rien n’est improvisé, les meilleurs techniciens sont requis pour que le show soit total. Au fur et à mesure des années, les équipements se sont spécialisés, ont même été conçus et construits à la demande !

[accordion title=’1997 : la tournée des stades’]Début 1997, Radiohead a prévu une longue tournée, mais dans des salles modestes. Le succès est là, mais il est encore timide. La sortie d’OK Computer va tout bouleverser, on va au dernier moment changer les lieux de passages pour des zéniths. Les places s’arrachent un peu partout, il faut donc suivre niveau infrastructure !

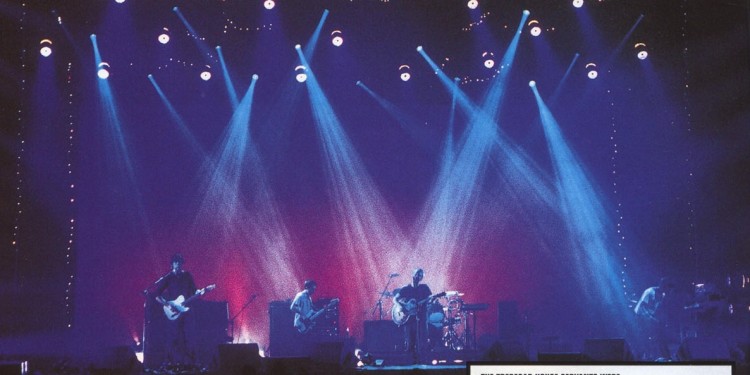

Déjà à l’époque, c’est Andi Watson qui est aux commandes des lumières. Aussi bien ce dernier que Thom Yorke ont un mauvais souvenir d’un concert, celui de Glastonbury :

[quote cite=’Print, 21 avril 2011′ align=’none’]If you could go back in time to witness one live show, which one would it be? And why?

Probably Radiohead at Glastonbury in 1997. My recollection of the Radiohead show is somewhat different to most people. It is often mentioned as one of the greatest gigs of all time but I had an utter nightmare on my hands. The desk dumped chunks of its memory as the band walked on stage; a lot of the lights were not working properly and it was an incredibly stressful experience. However, everyone I spoke to thought it looked amazing. I thought it was awful. I’d quite like to go back and watch that gig from the audience, although I’m not sure I would want to ever relive that original evening.[/quote][/accordion]

[accordion title=’2000 : des lieux intimes à la tente’]

| Transporteur : Mc Guinness (Europe) Fourniture de la tente Kayam (septembre 2000) : Rudi Enos Design |

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Eté 2000 : une scène intime, en plein air[/button]

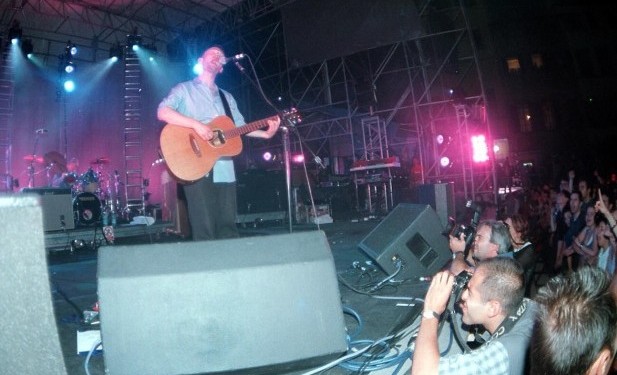

Courant été 2000, Radiohead fait une pré-tournée en Europe pour tester ses chansons, dans des lieux bien plus intimes que ceux connus en 1997 : des théâtres antiques (Arles, Vaison la Romaine (annulé au dernier moment))… de petites et très jolies places (Santa Croce à Florence)… des petites salles (le Grand Rex, à Paris)….

Un joli set de photos pour le concert à Monza en juin : https://www.flickr.com/photos/streetspirit73/sets/72157603453180042

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Fin 2000 : la tente Kayam[/button]

Pour la seconde partie de la tournée, après septembre 2000, le groupe a une idée de fou : tourner dans une tente géante, d’une capacité de 10 000 places, avec son propre équipement bien calibré, qu’on installerait à la périphérie des grandes villes, au lieu de s’installer dans des salles “institutionnelles” et parfois mal conçues pour des concerts. Cela permettrait également, et surtout d’ailleurs, de s’affranchir des sponsors. La lecture récente de No Logo de Naomi Klein les a convaincus : La tournée se fera donc en tente Kayam bleue.

[quote cite=’compte rendu d’une interview du groupe par 3FM, mai 2000′ align=’none’]When asked why they were bringing their own tent, Jonny said, “We don’t want to play in those venues that are designed for sport and have Coca-Cola adverts everywhere. That’s not what we want to do, really.”

The band were also asked why they weren’t going to play the Pinkpop and other festivals to which Colin replied, “The important reason for not playing Pinkpop is that we’ve already played Glastonbury before the release of OK Computer and we just don’t repeat what we’ve done before and which is playing a big festival before the release of an album.”[/quote]

[quote cite=’PopCulture Press #50, octobre 2000′ align=’none’]Greenwood discusses the change while bemoaning the state of most music venues, “That was more about getting away from big sports halls with beer adverts that sound awful and don’t look much better. People come and see you and they associate the last match they saw there or Celine Dion or whoever. It’s very used. Being in control of what people see and hear is the whole point of a concert really, when you don’t have that control for whatever reason it’s kind of disappointing.” They sought to remedy this by constructing their own self-contained venue in the form of a tent and lugged it around Europe to debut their new album. This new theater allowed them to control the sound exactly to their liking, and making something of a splash wherever they went. (Other members have referred to reading Naomi Klein’s No Logo – a dissection of the pervasive nature of ‘corporate multiculturalism’ and advertising as their primary choice for this ‘ad free’ environment but Greenwood shies away from agreeing completely. He reiterates that the sound is the most important element of this experiment for him.) [/quote]

La tente en question :

A l’intérieur, la scène :

D’un point de vue technique, on en apprend beaucoup sur le site Rudi Enos Design qui nous détaille la tente et sa scène,notamment en images: la structure Kayam (tente) est distribuée en Europe par Atticbest Ltd et dans le reste du monde par Rudi Enos Design. Pour ses dates dans 5 pays, le groupe a utilisé 3 structures Kayam. Radiohead avait testé les tentes à Wales et à Manchester auparavant.

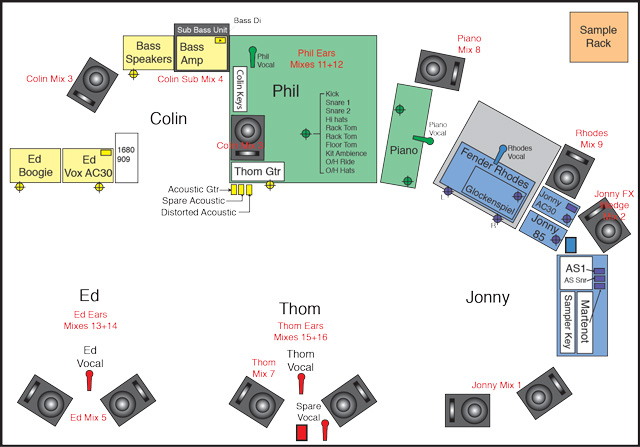

Ce shéma, notamment, présente toute l’infrastructure et l’équipement de la scène (sonorisation & éclairage) :

D’autres photos de la structure intérieure : http://www.rudienos.com/radiohead-tent-tour.html

Un article de l’époque, rédigé par John Arris pour Select revient sur un détail amusant : malgré tous les efforts du groupe pour s’affranchir des sponsors, on ne sert que de la Budweiser, dans des gobelets Budweiser !

[quote cite=’Kid A’s… Alright‘ align=’none’]In a corner of tonight’s field, just along from Ultimate Burger and to the left of the admirably non-corporate toastie van, there is the only beer outlet: a compact and bijou version of your average festival bar. Its queues are about ten people deep. It takes 20 minutes to get a drink. “It’s bloody Radiohead though, isn’t it?” groans one wag. “You’re not meant to have a good time.”

The wait, however, is not the main issue. The bar, as it turns out, is selling nothing other than Budweiser [actually, you can also get Virgin alcopops, but that’s hardly the point]. The beer is served from the can into big red cups – and the cups, of course, are branded. What a dirty Budweiser logo.

Select doesn’t want to be picky or anything, but this really doesn’t seem right. So, if only for the sake of conversational sport, we sidle up to Ed O’Brien at the brief aftershow soiree. it’s being held in an old farm outhouse that rather suggests the kind of room where you once hadbreakfast on a geography field trip. Everyone, incidentally, is drinking bottled Krononbourg.

So, Ed. Why are Budweiser doing all the beer?

“[Genuinely shocked] Are they?”

Oh yes.

“Isn’t it the Workers Co-op? [ie The Workers Beer Company]?”

No, you can only get a Budweiser. In a branded beer cup.

“Beer cup? OK. We’ll sort that out. That’ll change. I didn’t know that. You carry on learning. [In humorous voice] We haven’t changed the beer cups! We’ve failed!”[/quote]

Radiohead en 2000 était très fier et très content de sa tente, bien que conscient des limites (impossible d’emmener la tente aux Etats-Unis, notamment…)

[quote cite=’PopCulture Press #50, octobre 2000′ align=’none’]Sadly, the tent will not travel to America in Radiohead’s first Kid A foray but the band has been just as careful in their choice of venues. In this first pass the band will play only a handful of shows, do one television appearance (Saturday Night Live, which aired the week following this interview) and one radio appearance on the famous Morning Becomes Eclectic in Los Angeles. The choice, or lack of it, has raised more than a few eyebrows, which suits the band just fine. Greenwood insists the band will come back for future touring, but not as part of the standard grind, perhaps bringing the tent. “We’re going to try and come back and do a tour in a different way than we have before, something we’ll have fun doing.”[/quote]

L’aventure fera long feu et en 2001-2002, Radiohead va tester de nouveaux espaces : les amphithéâtres si possible en Europe, les lieux familiers (South Park à Oxford pour un concert exceptionnel en juillet), et toujours les grands complexes aux Etats-Unis à défaut de petites salles.

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Transporteur du matériel[/button]

Depuis 2000, Radiohead fait transporter son matériel en Europe par les camions de la société de l’Irlandais Franck McGuinness. Richard Young, manager de la production depuis 2003 en est très content :

[quote cite=”TPIMagazine, novembre 2012″]McGuiniess trucks have been working with Radiohead since the year 2000, so I inherited them, but they do a great job, they’ve got great drivers. [/quote]

Sur le site de la compagnie, on trouve aussi cette recommandation de Richard Young : “Great trucks, friendly, helpful drivers and a calm ‘can do’ attitude, even in the most bizarre of situations, continues to give me the peace of mind that I look for in a company. McGuinness.eu will continue to be my preferred trucking supplier for a long time to come”

[/accordion]

[accordion title=’2001 : la scène géante à Oxford’]

Pour le 7 juillet 2001 à Oxford, le groupe a prévu une scène digne d’un festival. Sous une tente ou pas ? eh bien non !

[quote cite=’BBC Radio 1 Evening Session, 29 mai 2001′ align=’none’]Steve (Lamarcq): “Tempo. Yeah, of course. Talking about… did any of you see the tent shows? The tent gigs?”

Amy: “Yeah. September 28th.”

Steve: “Which one was it, Amy?”

Amy: “The one in Glasgow, the first one. It was good.”

Steve: “Because they were very proud of their tent.”

John: “I’ve not seen the tent. Is it the same tent that’s going to South Park?”

Ed: “No, we’re not having… there’s no tent.”

John: “There’s no tent at South Park?”

Thom: “No tent as such, no.”

John: “Denied. No tent.”

Thom: “Denied.”

Steve: “What happens if it rains?”

Colin: “Everyone gets wet.”

Thom: “Yeah.”

Colin: “There are big trees, though, so…”

Thom: “Yeah, there’s big trees, and there’s lots of toilets.”

Steve: “I can’t believe I asked such a dumb question…”[/quote]

Il faut dire que 44 000 personnes sont attendues, 7 groupes vont se succéder dans le South park. Tout a été pensé par Radiohead, même les gobelets sont à l’effigie du groupe, pas de merchandising autre que celui décidé par le groupe…

Une photo du NME :

D’autres photos de Laurence Boisnard : http://771_radioheadoxford.voila.net/

[/accordion]

[accordion title=’La scène en 2002′]

Sonorisation : Adlib (Europe)? / Firehouse? (Amér.)

Transporteur : Mac Guinness (Europe)

Pilotage du système d’éclairage : Mac Wash

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Eclairage[/button]

On apprend sur un article de LSI online qu’Andi Watson, le designer de l’éclairage de scène, a fait appel à la technologie Mac Wash depuis 2002 sur la tournée européenne (il testait alors le Mac 2000 Wash). A priori, la collaboration s’est arrêtée après 2006, ou il a été fait le choix de faire confiance à Kinesys.

[/accordion]

[accordion title=’La scène en 2003′] Sonorisation : Adlib ? (Europe) / Firehouse (Amér.)

fourniture & location de matériel d’éclairage : Automation lighting

Transporteur : McGuinness

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Sonorisation[/button]

Pour la sonorisation des concerts sur le continent américain, Radiohead fait confiance depuis longtemps (au moins 2003) à la société de production new-yorkaise (de Red Hook pour être précis) Firehouse Production qui fournit les consoles, le système de monitoring, les microphones… Pour l’Europe, c’est Adlib qui fournit la même chose (on en est sûr pour 2008, on le suppose pour avant). En 2004, la société a été nommées au TEC awards (TEC = Technical, Excellence and Creativity awards!) pour la tournée Hail To The Thief.

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Eclairage[/button]

C’est à la société “Automation lighting”, spécialisée en fourniture & location de matériel d’éclairage de la scène, que Radiohead a fait appel pour sa tournée en 2003.

source : http://automation-lighting.com/gallery.html#

[quote cite=’TPI Magazine, juin 2008′ align=’none’]In 2003, our rider stated that our lighting power requirement was 600 Amps per phase. [/quote]

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Transporteur[/button]

En 2003-2006, le groupe a commencé à se passionner pour l’écologie et à essayer de réduire les émissions de carbone… Il a donc été demandé que les camions roulent au biofiul.

[quote cite=’TPI Magazine, juin 2008′ align=’none’]Although our report suggested that trucking wasn’t as responsible for our carbon footprint as other areas, we can still trim its impact,” commented Young. “Loading a truck too tightly and heavily, or too lightly, will prove uneconomical, so we’re careful to strike a good balance.[/quote]

[/accordion]

[accordion title=’La scène en 2004′]

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Eclairage[/button]

En 2004, la société Neg Earth Lights spécialisée dans la fourniture d’éclairages de grande ampleur, notamment de tournée a été sollicitée pour ses dates en Europe. Le contact du groupe est Dave Ridgeway, à Londres.

L’équivalent américain est Upstaging Inc. Le groupe traite affaire avec John Bahnick à Chicago.

[/accordion]

[accordion title=’La scène en 2005′]

Sonorisation : Adlib ? (Europe) / Firehouse (Amér.)

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Sonorisation[/button]

Voici une description complète de la scène donnée en 2005 par Graham Lees ; l’ingénieur son du groupe sur son blog :

[quote ]”Full stage technical spec What I am about to describe may seem a little foreign to some people who are reading it ! To others it will make a lot a sense ! Some of this has been copied from earlier blogs but there are a lot of topics of which I have not gone into detail about before. There are some aspects of the full set up which I am going to miss out because they are specific to the bands requirements and if I describe them Im sure everyone in a band will be using them (thats why they employ me ! I love to experiment and so do they)

Every item on stage has either a microphone or a direct connection allocated to it, in the case of Radiohead there were 64 inputs from the stage to the control systems. All the inputs from the stage go to a splitter box, often referred to as the stage box, this send the on stage information to 4 different sources, one going to FOH (front of house) where the information from stage is mixed for you, the audience, and is controlled by the mighty Jim Warren, who has been with the band since their very early days. The second send goes to me for the on stage mix. The third is used for the on stage technical mix and the forth is for external sources, for example, if the show is going to be recorded or broadcast on radio/TV as was the case at the UK V festivals this summer.

The Inputs

The Drums..

Kick Drum, Beyer M88, (Gate, Soft comp)

Snare 1, Shure SM57, (Soft Comp)

Snare 2, Shure SM57

Hi Hat, Shure KSM41

Rack 1, Sennheiser 504, (Gate)

Rack 2, Sennheiser 504, (Gate)

Floor, Sennheiser 504, (Gate)

Overhead Ride, Shure KSM32.

Overhead Hi Hats/ Crash, Shure KSM32.

Kit Ambience, a Shure MC50b, and placed in the middle of the drum kit, a nice ambient sound, good for the in-ear drum requests !

Jonny Toms, SM57 wireless, (Gate, Soft Comp)

Ed Toms, SM 57 wireless, (Gate, Soft Comp)

Mini Kick, Beyer M88 wireless. (Gate)

Mini Snare and Hat, Shure SM57 Wireless.

These channels are carry on and carry off items, therefore they are wireless so we can check they work before the appear on stage and there is no cable re patch necessary

The Vocals..

Thom uses a Shure Beta 87 with black pop shield. It is a microphone designed for very close proximity use, the pop shield is used to avoid direct contact with the metal end of the microphone. By employing the foam shield, Thom can sing very close to the mic with comfort. Therefore producing a loud and clear vocal sound. I reproduce the same consol settings for the spare vocal, the piano vocal, and the Rhodes piano vocal.

Phil uses a WCM15 vocal headset microphone, which can be converted to wireless if required.

Carry on vocals are at present : A beta 87 Wireless mic for Ed on There There, and a beta 87 wireless for Thom when he plays the Mini kit on one of the new songs !

The Keyboards,

The upright Piano has caused more problems than anything else on stage over the last 6 years. Everything possible to go wrong has, we even nearly tipped it over once ! A multitude of different microphones have been tried and then discarded. This tour heralds a new approach, the new piano has a stereo sample built in, and originally we were going to use this as a last resort spare signal. However we found that it combines very well with the newly installed Helpinstill Piano Sensor and an ambient mic, a Shure MC50b hanging inside the lid. Gone are the days of low end feedback, hi pass filters up on the mics, let the sampler do the bottom end.

The Fender Rhodes is mic-ed with 2 SM57s one on each speaker.

Both the Piano and the Rhodes move into the centre of the stage during the bands performance, therefore they are equipped with an umbilical containing the audio, video and power requirements.

There are various other midi-controlled keyboards dotted around the stage ; the sampler rack, which lives off to the side of the stage, controls them all. This unit also controls the drum samples. There are a total of 12 lines of information coming to me for different songs from this unit.

The Guitars.

There are 3 guitar set-ups on stage,

In the centre is Thom, he has a Vox AC30, mic-ed with a Sennheiser 609, apart from an array of footswitches, he has a control unit off stage.

Ed, on Thoms right, uses a Mesa Boogie, mic-ed with A Sennheiser 609 and a Vox AC30 mic-ed with a SM57. There is also a DI effect line. There is a mountain of pedals and off stage control involved.

To Thoms left is Jonny ; he uses a Vox AC30, mic-ed with a SM57, and a Fender 85, mic-ed with an Audix OM5. There is again a DI line for effects, and 2 lines from laptops, one of which is offstage. Again a huge array of pedals but with no off stage control !

The Bass guitar is Di-ed and Mic-ed with a Sennheiser 60

The Glockenspiel is mic-ed with 2 Shure MC50bs, and a couple of Drum machines are DI-ed

All of these inputs end their connection at the splitter box (also known as the stage box). We have 2 off these on the Radiohead set up. One has 56 inputs and the other has 20, this is more than we need and allows for some degree of flexibility. This is what the splitter box does ; on the stage side there are all the input connections, on the reverse there are 4 multi-pin outlets, between each input and output there is a small isolating transformer, these lower the possibility of interference. The first output supplies all the input channels to the FOH Digidesign conversion racks, the second goes to my conversion racks for the monitors, The third is for the on stage technical mixes and the forth is used if we are recording the show for a TV or radio broadcast.

The technical split was an idea developed as we expanded the monitor system at the outset of the Hail to the thief tour, it was based on the original idea from Duncan who had previously split his four main channels to a small mixer so that he could check that Jonny was OK during the show. Also, because there was so much backline equipment on the stage it meant that the crew were forever coming over to me to listen to their instruments if they suspected that there was a problem. There was a need for them to be able to hear selected channels during the show. This is what we designed ; the 48 lines from the main splitter are sent to a patching system that allows for any 12 channels can be sent to 4 separate locations on stage. At these locations, where the backline technicians live, there are small 12 channel Soundcraft Spirit desks and self powered JBL speakers. This has also proved invaluable one unforeseen reason ! Everyone now has Thoms vocal line on their speaker for the sound check so they can here him announce which song they are going to do next, this has made sound checks a lot faster, as now we all know when, for example, the piano needs pushing over to the centre of the stage. Once this system has been patched it has its lid left on for the tour ! All we need to do is to connect one large input cable and 4 small outputs ! One of the 4 systems has been commandeered by Ed, the 12 way desk is housed in the top of his FX rack, this is one point where he can pick up information being played by the other musicians on stage.

Line 48 ! This is the only line on the input list that I have not mentioned. This is for the technical communication system. Microphones, positioned at the front of house mixing desk, the monitor desk, the sampler rack and an on stage wireless microphone system are sent to a small mixing desk, mixed down to 1 line and sent to line 48, this signal is also sent to an on stage wireless in-ear system used by myself and Clive. This means that line 48 can be picked up everywhere on stage using the technical mix system.

The Outputs

There are 2 different ways in which I provide the musicians on stage with the information they require in order for them to perform. The first is using speakers on the floor, these are called wedges, and they contain both a large speaker for creating the bass part of the sound and a small speaker for producing the high frequencies. On this tour these were provided by Firehouse productions from New York. Secondly, in-ear monitors, which are custom, moulded for the individual musicians and are mixed in stereo. Radiohead use a combination of both of these, each member has determined over the years as to how they want to hear their mix.

Jonny only uses wedges, 1 in front of each of his guitar pedal boards and a third behind him for when he is playing keyboards and operating his drum machines. He has very minimal requirements and likes everything quite quiet ! He has a small amount of kick drum and snare drum, piano, acoustic guitar and a touch of Thoms vocal. He also has his own guitars and keyboards. Jonny also wears custom moulded ear defenders to cut down the overall level of sound. Once he is set up and running he doesnt require many changes during a show !

Ed uses a combination of floor wedges and in-ears. He uses off the shelf Shure E5s for his in-ears and has recently converted to Shures new E500s. The wedges are mainly used for kick and snare drums. His ears are mixed in stereo with different instruments placed at different points in the stereo field to give definition. For example he has his guitars in the centre of the mix, Thoms guitar is on the right hand side and Jonnys guitar on the left, the drums are mixed with the kick and snare in the centre and the rest of the kit positioned across them. He has everything from the stage in his ears.

Colin uses wedges alone, he has never tried in ears up to now, but has shown a lot of interest in trying them on the next tour. He also has a sub bass unit behind him to add extra weight on the low frequencies, mainly the kick drum and the drum machines. He has a full mix of everything on stage.

Phil uses just in-ear monitors. He again has a full stereo mix of everything on stage and as with the other in-ear users everything is positioned in the stereo field as if he was hearing the stage without using any monitoring. Subtle changes are made throughout the show, for example when Jonny starts a song I gently increase his level so he can get the timing correct.

Thom uses a combination of both wedges and in ears. He uses the in-ears like ear defenders and uses them at quite a low level. This cuts out all the stage sounds that he doesnt want to hear. Using the ears at a low level means that he can also clearly hear the wedge mix as well. In the wedges he has all the drums, all the guitars and keyboards and in his ears he has both his and Eds vocals, the acoustic guitar and piano and different amounts of his own guitar depending on the song being played.

There are also wedge mixes for the piano and the Fender Rhodes. The piano mix has both Thoms acoustic and electric guitars in it for when being played by Jonny.

The stage plan

This is the basic layout of the stage, not drawn to scale. When touring this is precisely measured everyday !

The Control

For this tour I decided to use a digital mixing console. On Jim Warrens recommendation I opted for the Digidesign D show. This is a fantastic piece of equipment ! Apart from sounding amazing it is not difficult to learn how to use and the facilities incorporated within it are second to none ! I will be using one on every opportunity from now on.[/quote]

[/accordion]

[accordion title=’La scène en 2006′]

En 2006, Thom demande à une association écologiste (Best Foot Forward) de calculer l’impact sur la planète d’une tournée.

[quote cite=’TPI Magazine, juin 2008′ align=’none’]To see how they could play a part in this, Radiohead commissioned a report in 2006 from Oxford-based ecological footprint analysis experts Best Foot Forward, which aimed to quantify the carbon footprint of touring, using data such as how many trucks the band might normally use; how many miles are travelled, how much equipment is transported, and what the audience do to get to each gig.[/quote]

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Eclairage[/button]

On apprend sur un article de LSI online qu’Andi Watson, le designer de l’éclairage de scène, a fait appel à la technologie Mac Wash depuis 2002 sur la tournée européenne (il testait alors le Mac 2000 Wash). Il a continué sur la tournée Hail To The Thief (ou une nouvelle fois il a beta-testé un nouveau système, le Mac Wash 700), et sur In Rainbows :

[quote cite=’http://www.lsionline.co.uk/news/story/Mac-700-Wash-debuts-on-Radiohead/GL4NJR, 19 July 2006′ align=’none’]Andi Watson, who helped beta-test the Mac 2000 Wash on a number of Radiohead’s European shows in 2002, and subsequently used the luminaire on the band’s Hail to the Thief tour, has real-world tested the Mac 700 Wash on this latest Radiohead tour (ndlr : en 2006).

“I am incredibly impressed with the Mac 700 Wash,” he says. “They are very complementary units to the existing 2K range. For their size the power consumption is quite low, the colours are wonderful and also the reliability of the units is fantastic. They have also been wonderful to program. We were the first to tour with the Mac 2K Wash and to be asked again with the Mac 700 Wash is just great. Our lead technician, Ed Jackson, who does a very thorough job of looking after the fixtures on the tour, has had to do very little to them.”

Watson has the 700 Wash units located on the floor and uses them to uplight cycs and side light the band. “For that the intensity is absolutely perfect,” he says. Lights are positioned at varying heights – in the overhead rig, on drop poles and on the floor – to create different layers of light. Other Mac units in the rig are Mac 2000 Performances, Mac 2000 Washes and Mac 250 Washes along with Atomic strobes.

“There are times when you don’t necessarily need that complete punch of a 2K,” says Watson. “Both the 2K Wash and 700 Wash serve their purpose but I found that the 700 Wash work even better with the Performances because the 2K Washes can sometimes outperform the profiles power wise, especially if you have a gobo with the animation wheel and you’re cutting the light intensity down.”

The lighting concept for the show was born out of conversations that Watson had with the band and incorporates video and the CCTV system they have developed over the years. “We didn’t want to do it in a conventional side screen kind of way,” says Watson. “We wanted to integrate the video even more than on the last tour so we brought the video onto the stage. The concept was to create a space in which the stage would appear a different shape and look differently from every angle. I wanted to create these perspective screens so we use 10 trapezoidal screens on stage which are angled and perspective twisted. It is almost a cubist way of looking at it.”

The screens are actually three-dimensional set pieces which were fabricated by Specialz of the UK with all softgoods by Blackout of the UK. Inside each screen are arrayed Color Kinetics iFlex SLX.

Ten cameras are used live during the show with video fed to the screens through Catalyst which allows Watson to then play with aspect ratios and distort the images. “Everything is live and nothing has been made in advance,” he says. “We have no pre-recorded content other than textures and graphical shapes. It is very spontaneous and we get some very beautiful effects.” All the video and LEDs are controlled with a combination of Catalyst and PixelMAD systems. Video equipment supply is by XL Video and Scenographic Ltd.

Watson projects colour effects from the Mac 700, 2000 and 250 Washes onto the screens as well. “I point the Mac 250 Washes at the screens, one per screen, and then project a black and white image on the screen so what you end up with is a colorized, dual toned effect. It’s a great look. I also project the 2K Washes onto the screens which is a more shadow and light effect that makes the screens look three-dimensional by creating back shadows. Again, the Mac 700 Washes get used on those too with others lighting the cyc. All washes point to the screens at some point.

“There is a massive variety of changes we can make in what is really a simple set up,” Watson concludes. “By combining the levels of the video with the iFlex and the wash effects on the screens we can get wonderful tricks of light and deception – great depth, three-dimensional looks and silhouettes for example.”

[/quote]

L’étude de l’impact écologique demandé par le groupe a donné un bilan du transport du matériel par camion + du déplacement des spectateurs… et pour les Etats Unis, les recherches montrent que 86% de l’impact sur la planète provient des spectateurs et leur déplacement en 2006, contre 97% en 2003… la conclusion a en tirer par le groupe est donc qu’il vaut mieux jouer en centre ville et plus dans des petites salles aux abords des cités, moins bien servies par les transport en commun. Par ailleurs, le groupe a alors décidé de massivement informer les fans avant les concerts.

[quote cite=’TPI Magazine, juin 2008′ align=’none’]According to Young, it demonstrated that trucks moving around Europe or America didn’t have anywhere near as much of an environmental impact as the movement of audiences to venues — especially sites outside of city centres where public transport services are not so reliable. In fact, according to Best Foot Forward’s project consultant, the research found that audience travel and consumption made up 86% of Radiohead’s 2006 US theatre tour footprint and 97% on their 2003 US amphitheatre tour.[/quote]

[/accordion]

[accordion title=’La scène en 2008′]

Sonorisation : Adlib (Europe) / Firehouse (Amér.)

Pilotage de l’éclairage : Kinesys

Fourniture du système de pilotage : Neg Earth

Transport du matériel : Andy Lovell & Sound Moves

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Eclairage[/button]

Petite révolution en 2008, qui va faire aller le groupe encore plus loin dans ses considérations écologistes : tout part d’un constat de Richard Young qui cherche une idée pour réduire le nombre de générateurs. Il trouve qu’il y en a trop, et qu’ils polluent beaucoup… Les générateurs au diesel servant à alimenter les lumières, pourquoi ne pas changer le système d’éclairage et passer aux LEDs ? Il en parle donc à Andi Watson qui le suit dans le projet :

[quote cite=’TPI magazine, juin 2008′ align=’none’] “The problem with diesel generators is that regardless of whether you’re pulling 100% or 10% of the available power, you’re still pumping emissions. I asked [lighting, video & set designer] Andi Watson if we could run our show without dimmers because they tend to place the most demand on generators. Removing dimmers would mean that we’d be pulling a constant power supply and therefore we’d be able to scale our generator requirement appropriately.

“Once Andi understood the importance of what we were trying to achieve, he suggested we completely base the lighting plot around LED sources. Although they don’t pull any power when they’re not on, the power that they draw when they are on is much, much less.

“In 2003, our rider stated that our lighting power requirement was 600 Amps per phase. By going LED, our maximum draw for each show on this tour, with everything on, including video and motors [but not including audio], is 140 Amps per phase. This means we’ve cut our total lighting power consumption by two-thirds.”

In spite of their planet-preserving attributes, LED lights are not to everyone’s taste. Some criticise them for a lack of brightness and colour definition, and will always prefer a molefay. Invariably, those people tend to be LDs of thrash metal bands who wouldn’t know subtlety if it punched them in the face.

Young jumps to the defence of Watson’s choice. “I think that Andi’s incredible lighting design proves that you can harness new technology without compromising on the art, and he’s really set a fantastic example. Interestingly, we have no moving lights, which I suppose is rare these days, but Andi’s shown that they’re by no means compulsory.

“We’re doing a lot of outdoor shows with early noise curfews, so we’ll start in daylight. As every LD will tell you, competing with the sun is futile, but with the LED sources designed in the format we have, the audience does have something engaging — and colourful — to look at.[/quote]

Richard Young, Andi Watson se rencontrent à plusieurs reprises fin 2007 pour mettre au point une nouvelle façon d’éclairer la scène. Après des tests, on décide de passer aux tubes LEDS, ainsi qu’aux spots LEDs et à la technologie Color® Reach Powercore de chez I-pix. Richard Bleasdale de chez I-Pix est désormais convié aux réunions.

[quote cite=’Electric Product, 2008′ align=’none’]Always open to see how the set could be further improved Watson and Tour Production Manager Richard Young were shown pre-production units of the latest LED innovation namely Color® Reach Powercore which can project a staggering 5000 lumens of light over 500 feet.[/quote]

En janvier 2008, Specialz entre en scène afin de réfléchir à un système pour faire tenir la technologie choisie : tout le système d’éclairage est revu, et il utilisera une “forêt de LEDs”, pilotées par la technologie Catalyst et PixelMAD (contact du groupe : Richard Bleasdale, qui écrit un nouveau logiciel pour s’accorder à la volonté d’un éclairage 3D).

En janvier 2008, une rencontre au sommet réunit tout ce petit monde et le groupe lui-même à qui on présente des schéma de ce que sera la future scène, avec ses LED en tube & en “fleur” de 7 spots… et le système de pilotage de l’ensemble. En février, le marché est conclu, on passe à la réalisation. Mi-mars, c’est terminé et en on envoie par containers aux Etats-Unis (depuis l’Angleterre où le tout a été produit).

[quote cite=’Electric Product, 2008′ align=’none’]Needing no further convincing, 5 modules were supplied for the South American leg of the tour by Bristol based Utopium Lighting, the first rental company to fully invest in this ground breaking fixture.

Watson comments – “The ColorReach has such an awesome output that as soon as the units became available I wanted to use them.”

[/quote]

En parallèle, un système V9 est expédié des Etats-Unis pour être testé aux répétitions dans les studios Bray qui auront lieu dans la première semaine d’avril 2008, dans la banlieue de Londres.

Selon Andi Watson dans le livre, livre “Concert Lighting: Techniques, Art and Business” Par James Moody et Paul Dexter (page 268), la répétition va durer 3 semaines : une semaine où on “construit”, une semaine où on programme et une semaine où le groupe répète.

Vers la fin, Braine Dacup, un technicien lumière, prend l’avion et s’envole vers Chicago. Upstaging vient de livrer une partie du matériel qui lui a été commandé, et il essentiel que le tout soit testé avant le premier concert en Floride… et il faudra faire vite car il ne reste alors que 2 jours !

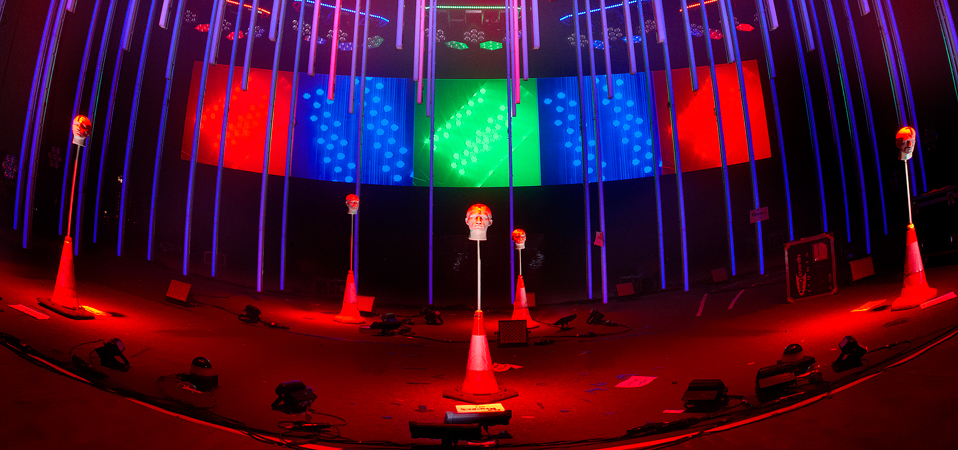

Un résumé clair et précis de la composition de la scène pour commencer :

– 48 spots LED BB7 autour de la scène

– 5 écrans produits par Specialz

– 48 spots LED BB4 sur les poutrelles.

– 25 écrans i-Pix Satellite avec un film holographique au sol

[quote cite=’http://www.jimonlight.com/2008/08/18/ipix-and-radiohead-awesome-video/‘ align=’none’]Radiohead lighting and visuals designer Andi Watson is using 48 of the BB7 10 degree spot LED fixtures around his rig – with 25 of the units in five custom 5-way frames produced by Specialz. Watson is also using 48 of the new BB4 wash luminaire models on his FOH truss. 25 i-Pix Satellite units with a holographic film are mounted on the floor in and around the backline to light Radiohead at close quarters.[/quote]

Pour la description du matériel, on a de nombreux détails : En Europe, c’est Neg Earth Lights, Upstagings en Amérique du Nord, deux fournisseurs de matériels qui sont choisis. Par conséquent les deux sociétés passent contrat pour l’achat du matériel, designé et pensé par Catalyst et PixelMAD.

[quote cite=’TPI magazine, juin 2008′ align=’none’]

Neg Earth Lights is the tour’s overall lighting contractor (Upstaging in North America), and Watson’s design has been enabled in a major way by Catalyst and PixelMAD products, and especially Richard Bleasdale who has written new versions of the software that interface brilliantly with the three-dimensional aspects of the production design’s unmissable core theme: the forest of hanging LED tubes.[/quote]

Le choix d’Andi Watson et de Richard Young s’est porté sur les Labs VersaTubes, parce qu’ils se déclinent en de nombreux formats, tout en restant légers et robustes.

[quote cite=’TPI magazine, juin 2008′ align=’none’]

“After looking around, the Element Labs VersaTubes lent themselves very well to this format as they were were physically the lightest and most robust option available,” said Young.[/quote]

Le groupe va donc passer commande de 543 tubes (tige de 9m et 1,2 m) placés en position verticale, statiques pendant les concerts. Comme il faut presque 3 heures pour installer le tout, il va devenir essentiel de trouver une parade pour gagner du temps… et c’est ainsi qu’on va arriver au désign final, en pensant à une “tab track” (une rangée de tubes ?)

[quote cite=’TPI magazine, juin 2008′ align=’none’]The hanging VersaTubes — 543 in total, across each touring system — are rigged vertically in 9m rods, 1.2m apart. They are static during the show, but take three hours to install during the load-in. “We needed to come up with a system to deploy the tubes into the show position quickly and efficiently. After exploring a few options, a tab track was suggested, and we arrived at the final design.”[/quote]

Le détail (très) technique de l’installation du système de tubes LED, pensée par Keith Owen de chez Specialz :

[quote cite=’TPI magazine, juin 2008′ align=’none’]Radiohead’s production hired the services of Specialz, whose technical director, Keith Owen, based the design around a 2m aluminium substrate with two VersaTubes permanently affixed. The substrates were joined together into their show length with a spigot and clevis pin, and are transported in their own custom built dollies.

Additionally, the existing VersaTube three-pin mains and four-pin data cables were designed out with a quick release seven-way adaptor, making mains and data connection between the individual substrates very quick in a show-build situation.

The deployment consisted of six 56ft heavy duty tab tracks with 12 scenery runners per run, to which the 2m substrates were attached. The tab track was joined by aluminium ‘yokes’ in pairs and attached to three runs of general purpose trussing. Specialz designed three master track ends which travel with the production in which the tab track draw cables, the scenery hangers, the spacing cable and the VersaTube buffer boxes all travel pre-rigged. [/quote]

I-pix, compagnie anglais, a travaillé sur le remplacement des anciens murs des spots par 4 (“four-cell 20° BB4 RGB clusters”), les BB4. C’est en particulier Chris Ewington, de chez I-Pix, qui a imaginé avec Andi-Watson, des spots LEDS regroupés par 7 nouvelle génération, les “BB7”, inclinables à 10°, qui vont être testés pour la première fois sur cette tournée 2008 :

[quote cite=’TPI magazine, juin 2008′ align=’none’]The other main fixtures come from UK manufacturer i-Pix, whose four-cell 20° BB4 RGB clusters are amazingly bright and do a sterling job of replacing conventional audience blinders on the front truss.

In conjunction with Watson, Chris Ewington at i-Pix has developed a narrow-beam [10°] LED spotlight with seven cells [the BB7], and this tour will be the first to use it. “There are currently 98 BB7s in the world and we’re using all of them for this tour!” smiled Young.[/quote]

97 de ces “fleurs” de spots ont été fabriqués et son utilisées par le groupe sur scène. Description de l’installation :

[quote cite=’TPI magazine, juin 2008′ align=’none’]Forty-eight of the BB7s are in various positions around the rig, [/quote]

Et pour parachever l’installation lumineuse, 5 écrans conçus par Philips, mis en scène par Specialzs, surnommés par Andi Watson les “Quins” et pilotés par le système Kinesys (voir ci dessous, Radiohead a quitté Mac Wash pour Kinesys en 2008) .

[quote cite=’TPI magazine, juin 2008′ align=’none’]including 25 split into five custom five-way frames — also designed by Specialz and named ‘Quins’. These are Kinesys-controlled flying frames, designed to fly straight out of their transport dollies and retain their show focus.[/quote]

-> Pour les fans de la technologie, un dossier “cas d’étude” de chez Philips.

On notera que finalement, le groupe optera pour 6 écrans.

Niveau éclairage, I-pix conseille d’ajouter 14 spots holographiques, installés au sol le long de la scène. C’est Ewington qui avait remarqué des prototypes lors de concerts aux Etats-Unis en 2007. En 2008, il présentait la nouveauté à Andi Watson et Richard Beller. I-pix a alors reçu une commande de 206 de ces spots (qui seraient partagés entre les scènes sur chaque continent) à honorer en 5 semaines !

[quote cite=’TPI magazine, juin 2008′ align=’none’]Also from i-Pix, there are 14 Satellites with holographic film mounted on the floor, in and around the backline, to up- and cross-light the band at close quarters.

This project started when Ewington visited the U.S. last October to see a new prototype narrow optic. He then showed Watson the BB4 which was already in production this January, along with a test rig of the embryonic idea he had for the BB7, without optics. Once the new optic became available, Ewington sourced the first 12 and again met Watson in March, along with Richard Young and lighting crew chief Andy Beller, and showed the first prototype BB7 with the new narrow optic.

Watson judged the fixture to be exactly what he wanted, after which i-Pix priced up the project and received an order to produce 206 fixtures (enough for two rigs) from scratch in just over five weeks.[/quote]

Ewington commented: “From our experience, most shows spend months in discussion and a maximum of six weeks in prep, so this timescale did not come as a surprise. The Satellite was developed under similar circumstances to coincide with Radiohead’s last tour.”

The BB4 uses custom Lamina TitanTurbo LED light engine modules — the fixture consumes 120W at 240V, on full power — and the evolution of the BB series produced the electronic and mechanical building blocks that could be applied to the new BB7 using the narrow optic. The BB7 uses the same Lamina TitanTurbo light engine and consumes 210W at 240V. Both fixtures feature 16-bit resolution for finer control of colour choice, which is in the billions.

The design period was condensed from six months to four days, the components were produced in two weeks and the units built over two weeks. “It was not a case of penalties for late delivery — we just had to do it,” elucidated Ewington.

“Andi put his trust in us before when he integrated PixelLines into his groundbreaking show for Radiohead back in 2003. He relied on us again in 2005 and in 2008 he’s really upped the ante! We all appreciated Andi taking a massive leap of faith in having the courage to dispense completely with conventional lighting in his show. Not having a single discharge or incandescent lamp in the design, sets a new benchmark at least a couple of years from what we had anticipated.”

Other light sources making an appearance in Watson’s design are Color Kinetics iW Blasts — “they provide what is probably the most natural-looking white light from any LED fixture,” said Young — and Pulsar RGB ChromaFloods.

The scenic design is completed by Blackout’s provision of black velvet velour truss borders and backdrops, plus a 48′ x 18′ black trevira kabuki reveal drape.

Watson controls the entire lighting rig from his favoured grandMA console, and works alongside lighting crew chief Andy Beller and technicians Nick Barton, Blaine Dracup, Tommy Green, Ian Lomas and Ed Jackson, as well as carpenter Johannes Soelter and head rigger Seth Cook.

[/quote]

Pour ce qui est de l’automatisation des systèmes d’éclairage, Radiohead met fin, semble-t-il, à son contrat avec Mac wash pour s’offrir désormais les services de Kinesys.

On apprend sur le site de Kinesys beaucoup de détails sur l’utilisation de leur technologie par Radiohead. On sait ainsi qu’Andi Watson, leur designer de l’éclairage, a fait appel aux services de Kinesys depuis au moins 2008, et que c’est Andy Beller qui pilote le système.

En 2008, on en était au système “Elevation 1” contrôlé par le logiciel PC vector :

[quote cite=’http://kinesys.co.uk/news/kinesys_on_radiohead/P40‘ align=’none’]A fifteen point Kinesys automation system consisting of Elevation 1+ drive units and PC based Vector control is being used by on Radiohead’s 2008 world tour.

The system was specified by lighting designer Andi Watson and is being operated by lighting crew chief Andy Beller from the side of stage. It has been supplied by rental company Neg Earth Lights who are also providing other lighting equipment to the tour.

The Elevation 1+’s are being used in conjunction with CM Prostar hoists, three each of which are being used to move the “Quins”, five custom built flying frames each containing 5 BB7 LED wash lights. The rig includes many customized LED fixtures developed by UK manufacturer i-Pix including the BB7s

The whole lighting rig is LED based with no conventional moving lights, so the Quins – moved by the Kinesys system – have effectively become the moving light elements of the show. They are programmed into 30 different presets and move into different positions for each song of the set. Each ‘Quin’ is focused on a different band member.

Beller has used Kinesys automation on many previous projects, the first was on the 2004 Dido tour. “It’s very straightforward to set up, logical to operate and a highly versatile system” he comments[/quote]

Le système Kinesys a été fourni au groupe par Neg Earth Lights.

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Sonorisation[/button]

Pour la sonorisation des concerts en Europe, Radiohead fait confiance à la société de production Adlib Audio (de Liverpool) qui fournit les consoles, le système de monitoring, les microphones… Pour le continent américain, c’est Firehouse Production qui fournit la même chose.

Voici le détails de ce qu’Adlib Audio a livré à Radiohead en 2008 :

[quote cite=’L-acoustic.com, novembre 2012′ align=’none’]Liverpool based technical solution specialist Adlib’s audio division supplied an L-ACOUSTICS K1 sound system and delays for the European leg of Radiohead’s current world tour.

They also supplied two of their top engineers – Tony Szabo and George Puttock – who worked with the Radiohead audio team to ensure that the band’s quest for producing the very best sonic audience experience is achieved.

On the road, the sound crew is headed by FOH engineer Jim Warren, monitor engineer Mike Prowda and production systems designer Sherif el Barbari. Also integral to this set-up is Ross Anderson, who looks after Prowda and Brett Taylor, from New York based US audio contractor Firehouse Productions, who is overseeing the delays.

Adlib was asked to provide a quote for the tour by Radiohead’s production Manager Richard Young, and were delighted when selected. Adlib’s Director Dave Jones says “Radiohead are renowned as complete perfectionists when it comes to all aspects of their show and production, so it was a real honour to be chosen to join the team”.

The K1 system is supplied to ‘K’ standards – The main hangs comprise 14 elements of K1 per side with four KARA downfills, and next to these is an array of eight flown K1 SB subs a side.

The side/outer left-and-right hangs are made up from 10 x K1 speakers with 6 x KARA downfills, which can be split into two arrays per side for the larger venues.

On the floor are 24 L-ACOUSTICS SB28 subs in a left-centre-right cardioid arrangement. The delay system is flown just behind FOH, consisting of three hangs, each of nine L-ACOUSTICS KUDO. The corresponding amp racks are flown directly behind each of the delay stacks to give the best sound for the audience, which is always the main concern of the band.

Radiohead are touring with their own FOH control and complete monitor system.

Additionally, Adlib is supplying four ARCS speakers per side for front fills and six KARA lip fills positioned along the front of the stage.

The biggest daily challenge is the rigging and getting a large speaker system in precisely the correct places for optimisation. Adlib is also supplying their own customised motor controllers, designed specifically to be used with line array PAs, which help make the PA rigging a smooth and efficient operation.

Larger venues like the O2 in London feature over 90 rigging points, and the daily build schedule for the stage and production set up is also extremely busy and needs to slot together like a jig-saw puzzle, with everything in its right place!

Tony Szabo has really enjoyed working to such demanding standards. “The Radiohead crew are all brilliant as well as very talented in their fields,” he comments, “All departments work together symbiotically and it’s a big collaboration which produces an amazing end result”.[/quote]

Voici le détails de ce que Firehouse a livré à Radiohead en 2008 :

[quote cite=’L-acoustic.com‘ align=’none’]On the band’s previous North American trek in 2008, Firehouse officially put K1 through the world’s first high-profile tour run. [/quote]

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Transport du matériel & considérations écologiques[/button]

Richard Young, le manager des tournées du groupe, nous apprend dans cet interview donnée à TPI magazine que c’est la société Sound Moves, et en particulier l’agent Andy Lovell qui s’occupe qui de la logistique du matériel du groupe lors des tournées. En 2008, comme tous les autres interlocuteurs de Radiohead, il a du suivre les exigence écologistes : faire naviguer le matériel vers les Etats-Unis ou le Japon au lieu de le faire voler. Le groupe collabore alors Maersk (bateaux).

Richard Young, le manager du groupe, justifie dans cette interview la volonté du groupe de faire voyager son matériel plutôt que de doubler son set sur chaque continent et ainsi anihiler l’obligation du déplacement par mer :

[quote cite=’TPI magazine, juin 2008′ align=’none’]Arguably the most significant move of all, encouraged by the Best Foot Forward report, was to adopt a ‘minimum air freight’ policy, said Young.

“We looked at all the costs and implications, and decided that sea freight was the best way forward. We could have gone to the extreme and not shipped anything, and just rented in each territory, but that wouldn’t work with this band. Thom, for instance, likes to use his vintage Fender Twin amp, and there’s no guarantee he’d get something in precisely the same condition anywhere else.”

The ‘safer’ standard elements, like PA, consoles, motors, truss and microphones, are being rented locally, but elsewhere, the answer was to source the nearest possible duplicate set of everything — backline and lights — to send in a container via sea freight to America, and then on to Japan.

Young: “All the equipment we’re using in rehearsal will remain in the UK for our shows here. With the sea route, it’s important to make allowances for any possible delays — and believe me, delays are very likely!

“Air freight is very much based on call and response, whereas with the sea option, your freight is just added to a list of things they need to deal with, which means it could be days before it leaves the country. Then there’s the journey itself. On average, it takes 12 days to reach New York from the UK and you also need to factor in a couple of days for customs clearance.”

The crew weren’t taking any chances. The container was sent early enough for it to arrive in Miami on April 21.

Young continued: “Some might argue that, other than the vintage equipment, we’re adding to our carbon footprint by manufacturing certain elements of our duplicate kit, but what they fail to appreciate is that all of this kit will be reused, time and time again.

“On balance, I think we’re being a lot more responsible. We estimate that we’ve cut our normal air freight package of 20 tonnes down to a mere one tonne, and that’s made up of the 12 vintage guitars that the band will not go on stage without.

“Andy Lovell at Sound Moves is our regular freight agent, and I think the whole sea freight operation for this tour has proved to be as much of a learning curve for him as it has for us, because air freight has been the tour standard for so long!

“Hopefully, by successfully taking the risks that we have, and making sea freight a credible alternative, it could lead to good working relationships with shipping companies like Maersk, who may see fit to prioritise our needs and reduce delays.”

[/quote]

Le transporteur camion choisi est toujours Mac Guinness pour l’Europe.[/accordion]

[accordion title=’La scène en 2010′]

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Transport[/button]

Pour le transport du matériel en Europe, c’est toujours les fidèles camions Mc Guinness qui officient, et ce n’est pas toujours de tout repos comme le montre cette anecdote racontée par Plank sur son blog :

[quote cite=”Le blog de Plank, mai 2010″]the second day there was overshadowed by the truck drivers strike going on in Spain and the border being blocked, a massive headache for production department having to make plans A- Z with everything changing every five minutes….eventually we resorted to various unconventional ways round the blockage which involved being up all night and splitting up gear and personnel……..[/quote]

Les fans de Radiohead passionnés de camions (et on les salue !) seront sûrement ravis d’apprendre qu’en 2009 McGuinness a renouvelé ses camions pour choisir 6 nouveaux Volvo qui respectent au mieux la planète : “six Volvo FH-480 4×2 Euro 5 powered extra-low height tractor units (..;)The new trucks were specified with full air suspension on tractors and trailers as well as I-Shift transmission and Globetrotter XL cabs. All feature SCR technology to achieve compliance with Euro 5. The new Volvo’s bring the McGuiness fleet up to 23 plus 50 specially-built step frame and flat floor box trailers (made by Montracon and Talson).

[/accordion]

[accordion title=’La scène en 2012′]

Avril : Sonorisation : Firehouse

Pilotage de l’éclairage : Kinesys

2012 est une année noire pour radiohead, puisqu’en juin, quelques heures avant un concert à Toronto, la scène va s’effondrer blessant et tuant… En moins de 3 mois, tout va être reconstruit à l’identique pour reprendre la route dès octobre.

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Eclairage[/button]

Depuis 2008, le pilotage de l’éclairage est géré par le système Kinesys. Ainsi, pour Coachella :

En 2012, à Coachella :

[quote cite=’http://www.plsn.com/current-issue/41-production-profile/9352-coachella-2012-a-tale-of-two-weekends.html‘ align=’none’]Radiohead (accompanied by a Kinesys-controlled dynamic array of a dozen 2-by-2-meter video screens)[/quote]

Après l’effondrement de la scène en juin 2012 à Toronto, il a fallu tout reconstruire dans l’urgence en 14 semaines… et ce fut mission impossible pour Kinesys, qui de plus ne faisait pas de prêt de matériel.

[quote cite=’TPI magazine, novembre 2012′ align=’none’]Kinesys supplied the original automation system, but as they don’t do rental, only sales, the 14 week wait period for a new system was too long, therefore that element had to go to a rental company which is where Stage Technologies stepped in [/quote]

[button style=’red’ icon=’iconic-right’ fullwidth=’true’]Sonorisation[/button]

Voici le détail de ce que Firehouse a fourni avril 2012 pour la tournée américaine :

[quote cite=’L-acoustic.com‘ align=’none’]

Firehouse Productions provides K1, KARA and KUDO rig for North American trek

RED HOOK, New York — Radiohead recently embarked on its first North American tour in four years and is firing on all cylinders with a full L-ACOUSTICS K1/KARA/KUDO system supplied by Firehouse Productions of Red Hook, NY.

The North American portion of the tour, which kicked off at Miami’s American Airlines Arena on February 27th, is divided into three legs, the last of which will wrap up at Toronto’s Downsview Park on June 16th before heading overseas to Europe, Southeast Asia, Japan, New Zealand and Australia.

For most of the arena stops on the domestic tour, Firehouse is deploying left and right arrays comprised of 14 K1 line source elements with four KARA hung below for downfill. Coverage for the far left and right audience areas is addressed by outfill arrays featuring 10 K1 with six KARA flown beneath.

Sub arrays of eight K1-SB are flown adjacent to both of the primary K1 hangs, while 24 SB28 groundstacked in cardioid mode bolster the low-end reinforcement. Horizontal arrays of four ARCS on each side of the stage provide nearfill, as do six dV-DOSC spread out across the stage lip.

For larger venues, Firehouse deploys a delay system exclusively comprised of KUDO featuring left, center and right arrays of nine enclosures each flown in back of the FOH mix position. Amplification and processing for all loudspeakers is provided by LA8 amplified controllers housed in LA-RAK touring racks.

At the helm of the system each night is Radiohead’s longtime FOH Mix Engineer Jim Warren, supported by System Designer/Engineer Sherif El Barbari and Firehouse System Tech Jamie Pollock.

According to Warren, “I have yet to find another system which combines the even coverage and the dynamic sensitivity of the L-ACOUSTICS K1/KARA system. With the use of KUDO delays in the larger arenas on this run, we have been able to further improve on the coverage, especially into the rear corners of the room, and have been able to minimize the amount of energy directed at areas where it was not required with very pleasing results.”

At Warren’s request, the tour’s mix position is also equipped with a pair of self-powered L-ACOUSTICS 108P and single 115P low-frequency extension cabinet. This small system acts as a reference when working on the mix from ProTools during the day as well as serves as a monitor during the show. A third 108P at FOH acts as a shout system for communication with the monitor mix area.

According to Rolling Stone magazine’s website, Radiohead front man Thom Yorke revealed that the band has worked up more than 75 songs for this tour, including additional new songs and deep-track B-sides.

“Radiohead’s list of songs to choose from each night is very diverse,” notes El Barbari, who designed the system. “When it comes to styles and facets, their music is extremely dynamic and ranges from very quiet to physically capturing, which requires a PA system that performs evenly throughout various SPL levels. K1 and the rest of the L-ACOUSTICS range of cabinets are well known for performing neutrally at all levels without changing tonality or coloring the sound, which makes this system the perfect match for a band like Radiohead.”

On the band’s previous North American trek in 2008, Firehouse officially put K1 through the world’s first high-profile tour run. According to El Barbari, who was extremely pleased with the results then, this year’s outing is even better thanks to the addition of KARA, digital AES cards for the LA8s, and the use of the new LA NETWORK MANAGER 2.0 software.

Following the North American leg, the tour turns to Liverpool-based Adlib Audio to provide a similar PA for the European and UK portion. Firehouse, however, will continue to supply the control for the full duration of the international tour.

[/quote]

Sur le site de la compagnie de transport Mc Guinness, qui se charge de transporter le matériel depuis 2000 , on apprend que pour la tournée de 2012, 12 camions ont été mobilisés :

“2012 saw Radiohead complete two separate European legs during their world tour. Eleven trucks were used and it finished in Antwerp in October. We have been working with the band for a number of years now and it was good to be back on the road with them again.”

LS-Live (site web : http://www.ls-live.com/) est une société de production spécialisée dans la création / fourniture de matériel de tournée : la structure de la scène, le cablage, l’assemblage des éléments… qui se présente ainsi

[quote cite=’http://www.ls-live.com/’ align=’none’]LS-Live is Europe’s biggest and best production rehearsal arena complex based in Wakefield, West Yorkshire. Voted Favourite Rehearsal Facility and Favourite Staging Company at the prestigious TPi Awards 2013, our 30,000 sq ft site in Wakefield offers a one-stop-shop rental solution for staging, set design and construction, automation and studio rehearsal space for the concert touring, TV & film, festival, experiential and installation sectors. Our team’s knowledge of the industry and can-do attitude have afforded us a client list that includes The Stone Roses, Jay-Z, Kasabian, Robbie Williams, J-Lo, Dizzee Rascal, The BBC and ITV.[/quote]

Pendant l’été 2012, Richard Kent et Richard Young ont décidé de faire appel à ses services pour la première fois (du moins semble-t-il…) car il fallait dans la précipitation recréer toute une scène. En effet, en juin 2012, juste avant le concert de Toronto, la scène s’était effrondrée, blessant et tuant des roadies… Le délai était cours, le groupe voulant reprendre la tournée dès octobre.

Ils ont ainsi rencontré Ben Brooks, le directeur de LS-live au studio Elstree pour passer en revue les dégâts et évaluer ce qu’il y avait à faire : tout étant en charpie (en particulier le piano de Thom…), il a fallu repartir de photos pour s’imaginer l’état premier de la scène :

[quote cite=’All Access‘ align=’none’]“We were greeted by mounds of bent metal and the remainder of the keys from Thom Yorke’s piano,” Brooks said. “It was one of those moments where you’re overwhelmed with the thought, ‘I hope this never happens to me’. It puts into question everything that you do.”

With no drawings of the original set available, the LS-Live team had to start from some photographs, what they had been told and the wreckage. The six winch frames from the upstage row in the roof had badly bent side plates and the six downstage ones that took most of the impact on collapse were completely buckled.[/quote]

Chez LS-live, on s’est donc activé pour tout recréer à l’identique en 3 semaines ! Le détail des prestations, raconté sur le site de LS-Live :

[quote cite=’http://www.ls-live.com/‘ align=’none’]Due to our decades of experience in aluminium engineering, structural design and set fabrication, we were brought in during the early stages of the rebuild to provide our expertise. Demanding in terms of time, logistics and complexity, the project challenged all of LS-Live’s resources across a period of three weeks, involving structural assessments, re-drawing detailed components from scratch, reverse engineering, testing, manufacturing, modifications and final assembly.

Having evaluated the damage to the winch frames, main truss syste, flying video screen and transport dolly, our team of structural engineers and designers began to create drawings of the original set from scratch, making alterations along the way.

We stripped the winch frames to analyse what was damaged beyond repair, removing all slewing motors and gearbox assemblies in the process. We measured and redrew all the components, incorporating requested modifications to video tile positions and cable routing.

We used new aluminium for the new winch frames, cut using a specialist abrasive water jet technique because they were too thick for laser cutting. After machining, we assembled the complete winch frames, installing fully tested slew motors and NDT (non-destructive testing) crack-checked cable management reelers.

LS-Live also re-designed the main truss system, to improve access and installation of the winch reels. We worked with independent structural engineer Lee Coverley to ensure the new designs could safely accommodate the weight load, before commissioning James Thomas Engineering to manufacture the system.

Finally, we supplied a 60ft by 32ft rolling house stage for the remainder of the tour and two 24ft by 12ft side LiteDeck platforms for the technicians. All was delivered on time and in budget after an emotional few weeks.[/quote]

Au final, une scène plus belle et plus solide a été livrée à temps, grâce au travail d’ingénieur engagée pour l’occasion.

[quote cite=’All Access‘ align=’none’]The company worked with independent structural engineer Lee Coverley to ensure the new designs could safely accommodate the weight load, before commissioning James Thomas Engineering for the manufacturing.

“All at LS-Live had mixed feelings about this project,” structural and mechanical engineer, Mark Blount, said. “We’re very proud of what we have achieved, but Scott Johnson died in that stage collapse. You can mend metal, but that won’t bring him back.[/quote]

Pour la fourniture des éclairages, la société Neg Earth Lights a été particulièrement sollicitée dans la précipitation par Richard Young pendant l’été, après le tragique et meurtrier effondrement de la scène en juin 2012 à Toronto.

Pour l’automatisation des éclairages, en 2012, Radiohead avait choisi Kinesys. Toutefois, l’effondrement de la scène en juin 2012 à Toronto les a obligés à faire appel en précipitation à Stage Technologies, qui a su répondre en 30 jours à la demande.

[quote cite=’TPI magazine, novembre 2012′ align=’none’]Kinesys supplied the original automation system, but as they don’t do rental, only sales, the 14 week wait period for a new system was too long, therefore that element had to go to a rental company which is where Stage Technologies stepped in [/quote]

[quote cite=’http://www.stagetech.com/node/1651, octobre 2012′ align=’none’]

When Radiohead needed new automation Stage Technologies delivered

Stage Technologies has been contracted by Radiohead Production Manager Richard Young and Richard Kent of Aerial Rigging Techniques to provide a 60 axis “pod” system running 12 free flying video screens on the Radiohead tour in Europe, New Zealand and Australia this autumn. Following a well-documented roof collapse earlier in the summer the tour’s automation system had to be replaced. Despite being in the midst of its busiest year to date the Stage Technologies rental team created a new bespoke system within 30 days.

Stage Technologies provided control for the band’s existing winch system including: 10 AU:tour control racks, a 60 axis system, plus new motor looms racks, desks and programming tools. Each pod in the system contains 4 point hoist winches each lifting a corner of the screen. Each is able to rotate to create multi-dimensional movement within the screens.

Stage Technologies Head of Training Alex Hitchcock, who managed the programming for the project, said “The Radiohead tour is a great example of what Stage Technologies can turn around in a short space of time. Creating the system and ensuring it was at Elstree studios in time for rehearsals was going to be a challenge but our team met it brilliantly.”

The band has a catalogue of 90 songs, each of which has any combination of 27 “presets” or looks for the screen positions; and each night of the daily touring has a differing set list. The team arrive onsite around 7am and expect to be fully rigged by 2pm because in many cases the concert doors open at 4pm. This is a slim window in which to program and test the show for each night.

Hitchcock said, “Programming the show is another test altogether and only really possible once the system is complete. Our solution, for now, is to model the screens geometry in 3D studio Max and employ the Stage Technologies toolkit to output axis profiles and “deads” for each preset to the winches. This allows the operators to pick the presets in order of the songs and simply re-time and save as a cue.”

Stage Technologies’ Director of Rentals Services Ted Moore said “When the call came I knew this was a big ask. Delivering something so quickly that had needed to interface with equipment that had already been produced once by someone else is always a challenge, but my team delivered with dedication, hard work and professionalism.”

[/quote]

[/accordion]

No Comment